SMAS Accreditation Explained

What is SMAS accreditation? it is a UK health and safety pre-qualification scheme used to assess whether contractors meet recognised standards for managing health and safety. It is widely accepted across construction and related industries and is often required before contractors can tender for work.

What Is SMAS Accreditation?

SMAS stands for Safety Management Advisory Services. SMAS accreditation is SSIP-recognised, meaning it follows the SSIP Core Criteria for assessing health and safety competence.

Achieving SMAS accreditation shows clients and principal contractors that your business manages risk effectively and complies with UK health and safety legislation.

What Does SMAS Accreditation Assess?

A SMAS assessment typically reviews:

- Health & Safety Policy

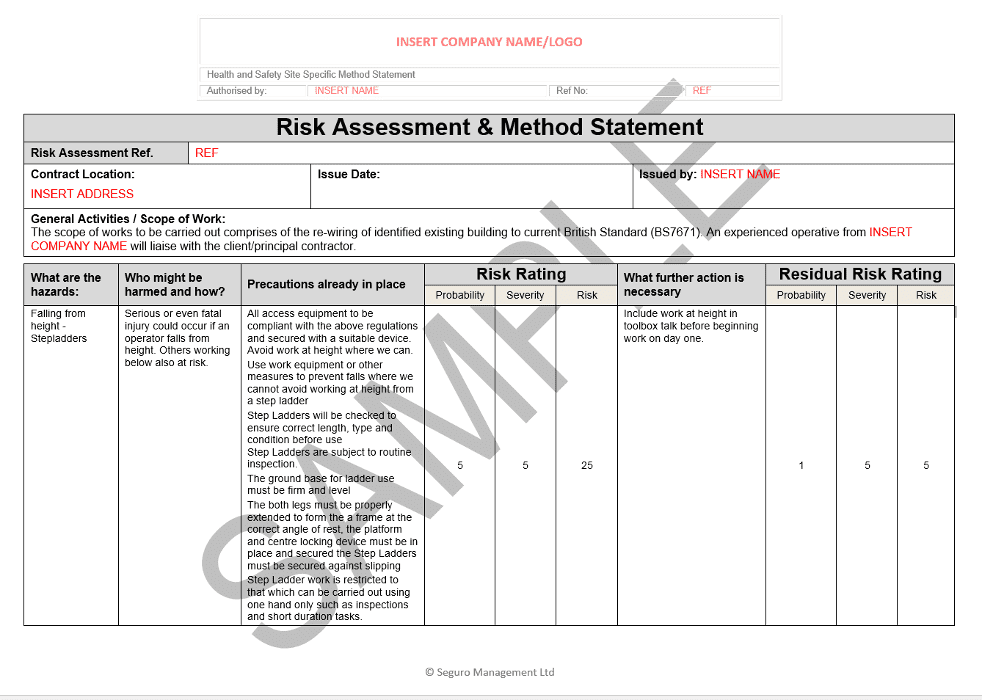

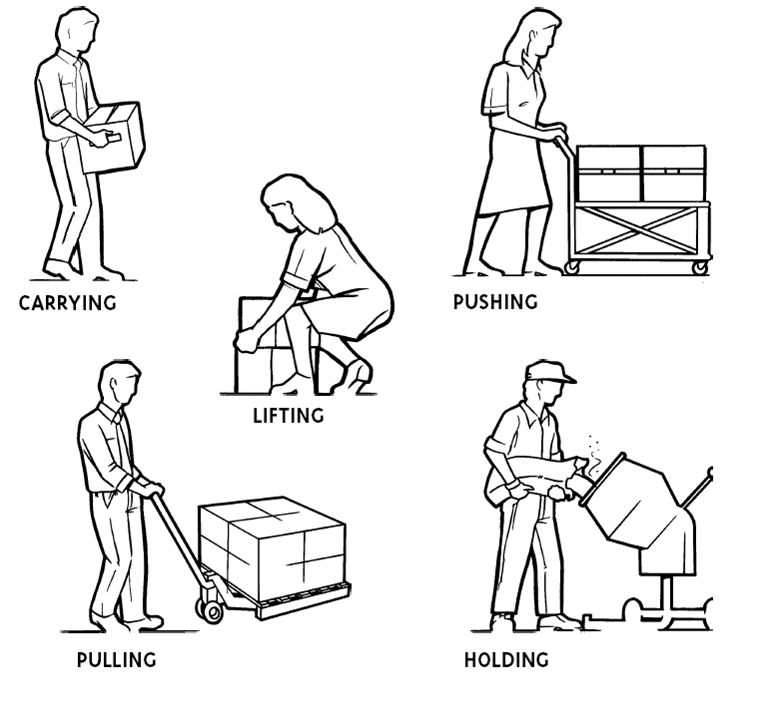

- Risk assessments and method statements (RAMS)

- Training and competence records

- Accident and incident reporting procedures

- Arrangements for managing subcontractors

The assessment is proportionate to your business size and risk profile.

Who Needs SMAS Accreditation?

SMAS accreditation is commonly required for:

- Construction contractors and subcontractors

- Electrical and mechanical contractors

- Facilities management and maintenance companies

- Businesses working for principal contractors or local authorities

For many buyers, SMAS is a minimum entry requirement.

Is SMAS the Same as SSIP?

No.

SSIP is the umbrella body, while SMAS is one of the accreditation schemes recognised under it. Holding SMAS demonstrates SSIP-aligned health and safety competence.

How Long Does SMAS Accreditation Last?

SMAS accreditation is valid for 12 months and must be renewed annually to keep your compliance status current.

Benefits of SMAS Accreditation

SMAS accreditation helps contractors to:

- Win more work

- Reduce repeated PQQ paperwork

- Demonstrate health and safety competence

- Meet client and procurement requirements

- Build credibility with buyers

How much does SMAS cost?

- Fixed Fee for helping with your accreditation, which will depend on the number of your employees.

- eLearning may be required

- Additional RAMS may be required

- Worksafe

- Worksafe PQQ

Why apply for your SMAS accreditation?

When you undertake your SMAS registration, you will be demonstrating that you meet the recognised standards required by any organisation looking to employ you as a contractor. Having your SMAS accreditation is almost certain to open more doors and lead to more opportunities – in turn generating more business and profit for you, ensuring your own workforce is protected by robust health and safety practices.

Submit your SMAS Accreditation with confidence

Getting SMAS approved depends on you satisfying the SMAS assessors on a wide range of compliance issues.

Which ones apply to you will depend on various factors relating to your business, so step one is to ensure you have the right support from the beginning.

- We support you every step of the way

- Competitive pricing with no hidden costs

- A quick, easy and hassle-free process

SMAS Approval Guide: How to Get SMAS Accredited

SMAS accreditation is an SSIP-recognised health and safety assessment used by clients and principal contractors to verify contractor competence. Following the correct steps helps avoid delays, failed assessments, and unnecessary costs.

Step 1: Check Whether SMAS Is Required

Before applying, confirm that SMAS is the scheme requested by your client or tender documents. Many buyers accept any SSIP scheme, while others specifically ask for SMAS.

Step 2: Appoint a Competent Person

Under Regulation 7 of the Management of Health and Safety at Work Regulations 1999, you must have access to competent health and safety advice. This can be:

- An in-house competent person, or

- An external health & safety consultant

SMAS will expect clear evidence of this.

Step 3: Prepare Your Core Health & Safety Documents

SMAS approval is evidence-based. You will typically need:

- A current Health & Safety Policy

- Risk Assessments and Method Statements (RAMS)

- Training and competence records

- Accident and incident reporting procedures

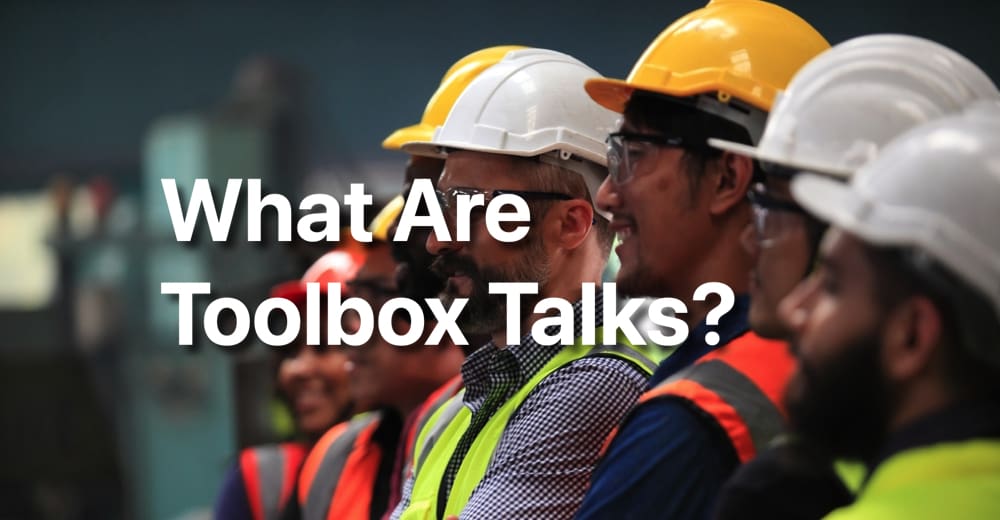

- Evidence of toolbox talks and inductions

Documents must be relevant to your actual work activities.

Step 4: Gather Company and Insurance Information

You will be asked to provide:

- Company details and structure

- Public and Employers’ Liability insurance certificates

- Business activities and workforce size

Ensure insurance limits meet typical client requirements.

Step 5: Complete the SMAS Application

Submit your application online via the SMAS portal, uploading all required documentation. Accuracy and consistency are critical at this stage.

Incomplete or generic submissions are the most common cause of delays.

Step 6: Respond to Assessor Queries

An assessor will review your submission and may raise clarification queries. Responding promptly and accurately helps keep the process moving and avoids rejection.

Step 7: Achieve SMAS Approval

Once approved, you will receive:

- SMAS certification

- Permission to use the SMAS logo

- Inclusion on the SMAS contractor database

- You can now reference SMAS in tenders and pre-qualification submissions.

Step 8: Maintain and Renew Annually

SMAS accreditation is valid for 12 months. Keep documents up to date and review your systems regularly to ensure a smooth renewal.

Common Reasons SMAS Applications Fail

- Out-of-date or generic policies

- Missing training records

- Poorly written RAMS

- No evidence of a competent person

Most failures are avoidable with proper preparation.

Summary

- SMAS is an SSIP-recognised accreditation

- Evidence-based health & safety assessment

- Requires competent person support

- Valid for 12 months

- Preparation is key to approval